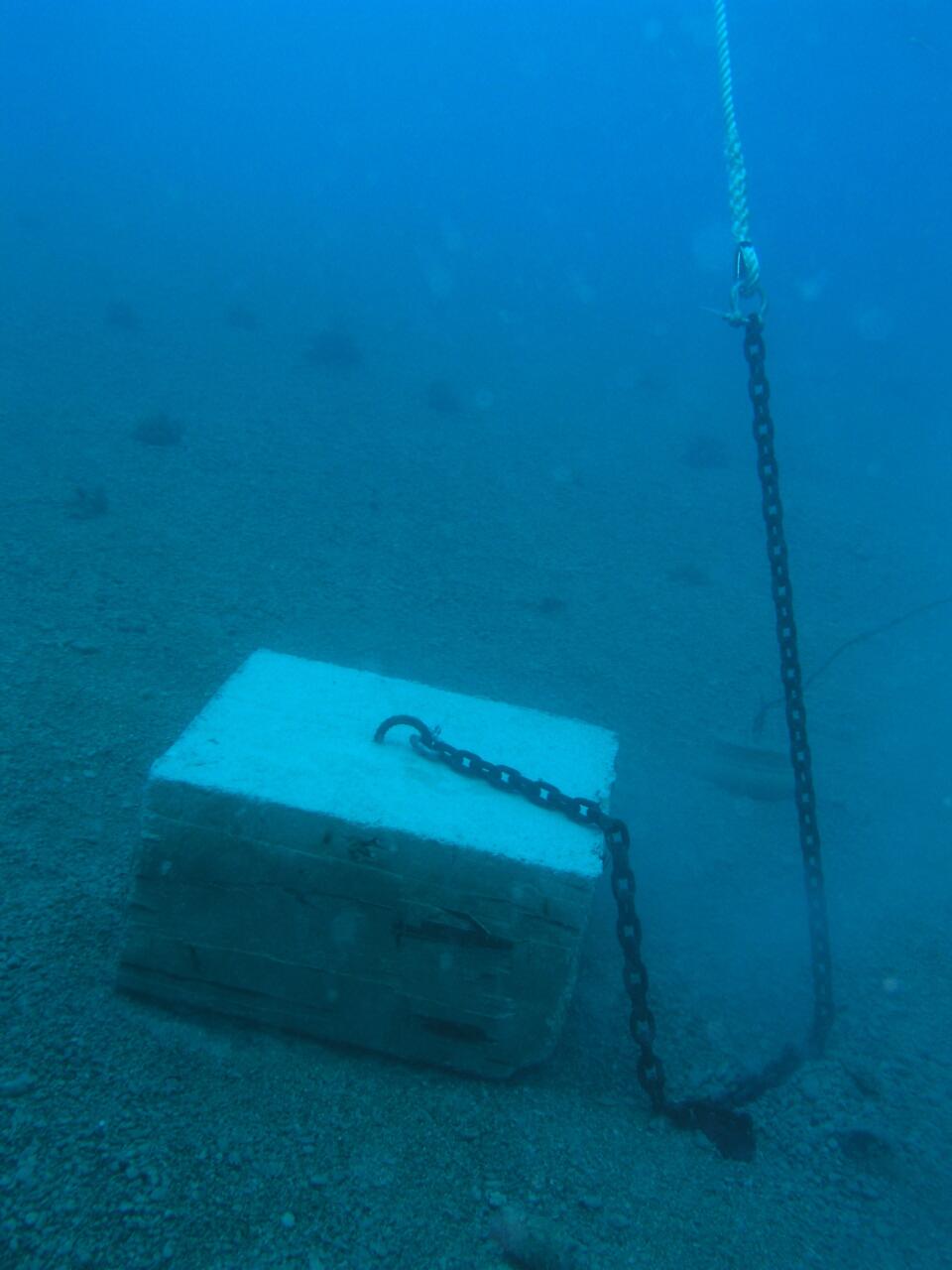

Sub-Merus Helix Anchoring System - Eliminates the Need for Concrete Blocks

The company Sub-Merus from Omiš represents and installs Helix geotechnical anchors – an environmentally friendly alternative to classic concrete anchor blocks. These spiral screw anchors, produced by American and French companies, provide exceptional tensile load capacity in relation to their own weight, with minimal impact on the marine ecosystem. For example, a Helix anchor with a breaking load capacity of 10 tons weighs only 30 kilograms, while to achieve the same load capacity, a classic concrete block submerged in the sea would have to have a mass of about 17 tons. In addition, such a block occupies a significant area of the seabed and, due to its volume and dimensions, can interfere with the navigation of sailboats in shallow bays.

This approach to establishing permanent nautical anchorages not only facilitates transport and installation in difficult-to-reach or shallow areas, but also significantly reduces safety and environmental risks. The visual chaos on the bottom caused by massive concrete blocks and catenary lines is obvious to visitors, while their negative impact on the marine ecosystem is immeasurable.

Helix anchors are drilled into the seabed sediment to a depth of 2–3 meters. After installation, the only visible element is the steel eye, which serves as the anchoring point for the mooring system, eliminating the need for massive concrete blocks and rotating chain lines. The main motive for using Helix anchors is environmental protection. These solutions significantly reduce damage to the marine ecosystem, especially in areas covered with seagrass.

The ecological mooring system includes a geotechnical anchor, a bottom and mooring line, and a buoy (64 l or 120 l), and can be adapted to the specifics of the project - especially the length of the moored vessel. In addition to the concrete block, the chain bottom line is also problematic, which, rotating together with the vessel, destroys all living things within a radius. Greater depth requires a longer chain to achieve the optimal anchoring angle, which further increases the damage to benthic communities. The solution is to install a bottom line with a buoy (raider) that lifts the entire system off the bottom.

Before installation, it is mandatory to conduct sounding and sampling and staking of the exact positions for future anchors. The installation process itself is not complicated - a 100 kg hydraulic machine is placed above the anchor and rotates at a speed of ten revolutions per minute. The machine can also rotate in the opposite direction and allows the anchor to be surveyed from the sediment if necessary, which, combined with the factory warranty of 30 years on the material, makes the system cost-effective and sustainable in the long term.

Installation takes approximately 20 minutes. The machine operator on land or on board follows the instructions of a pair of divers who center and correct the position of the anchor. This is followed by the connection of the bottom and mooring lines and the buoy. Upon completion, the system is immediately ready for use.

Sub-Merus is a certified company with the necessary permits and certificates for the production and installation of Helix anchors. These anchors have been tested and approved for use on various types of seabed, ensuring high safety and reliability. Helix anchors are suitable for use in a variety of locations – from river mouths and coastal zones to deep and shallow marine areas. The system is flexible and can be adapted to various sediment types, from soft silt to hard rock.

Although the initial price of Helix geotechnical anchors is slightly higher than the price of classic concrete blocks, the long-term cost-effectiveness is achieved especially in remote locations and shallower depths. Installation is quick and easy, and the system comes with a 30-year warranty. In conclusion, Helix anchors represent an innovative and environmentally friendly anchoring solution – offering high load capacity, minimal environmental impact and wide adaptability in application.

Photo: Tino Mrčelić